Powerful End to End Drawing, Quoting and Machinery File Generation Software for the Glass Industry.

The problem.

Even though it comes in flat panels, Glass isn't a simple product to measure and draw. Most of the time, glass panels, whether they be for shower screens, splashbacks, balustrading, wall cladding etc need to fit something that is already there, and anyone in the building industry will attest that plumb walls and level floors are a rarity. That means that glass needs to be measured and drawn with a high degree of accuracy.

Even worse, once it is tempered, it is almost impossible to modify. It either fits or it doesn't, which makes it quite an unforgiving material to work with.

Traditionally glass is measured and drawn by tradespeople who use traditional drawing equipment, e.g. pens and paper. This is a labour-intensive task, especially if you have a lot of glass to draw. It is very easy to make mistakes, miss dimensions and draw things that prove to be geometrically impossible. Not everyone is particularly good at drawing by hand, and unclear drawings are very easy to misinterpret.

After the drawings are created, they are then sent to a glass processing company for a quote and then to production. The challenge then becomes one of data entry. Often data is entered twice by the glass processor, and in some cases a third time. Once for quoting/costing and then the drawings themselves need to be created in a CAD system on order for the machinery to process the glass.

Data entry errors prove to be expensive and all too common, often not picked up until after the job has been produced, or even worse, delivered ready for installation.

Fortunately, there is a far better way!

The solution.

SplashCAD is a powerful yet easy to use integrated system whereby glass can be easily drawn, stored and shared. Drawings can be instantly sent to glass processing companies for quoting and ordering. Even better, no additional data entry is needed by the processor. The job can be quoted automatically from SplashCAD and only requires a quick validation before sending out.

Similarly, processing files are created by the system from the original drawings made by the measurer. No redrawing required.

How it works.

SplashCAD consists of 2 parts:

- SplashCAD Online is an online portal for creating jobs and generating drawings and requesting quotations by glass installers. A custom branded version can be linked directly to a glass processor's website for customers and installers to place orders.

And

- SplashCAD Desktop, a powerful windows desktop program for job management, quoting and file generation by the glass processor. Once a job is submitted via SplashCAD Online by the installer, it will automatically be accessible from the SplashCAD Desktop for quoting or production by the glass processor.

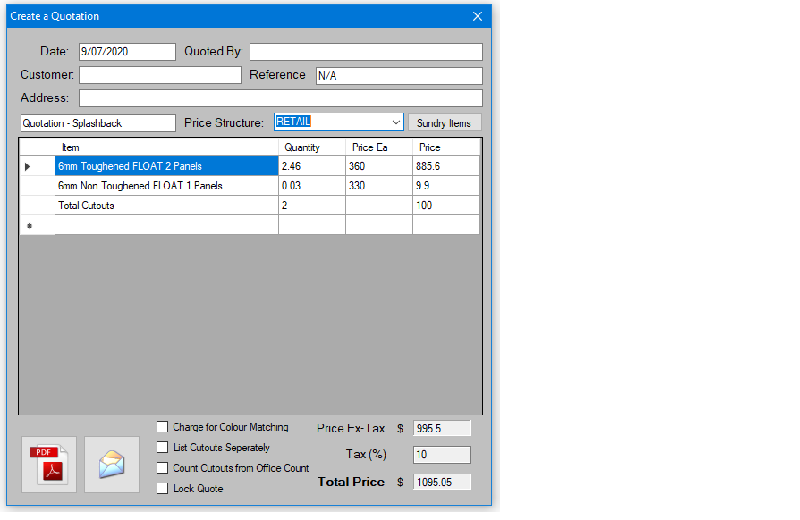

Quoting from within the System.

Using the integrated Pricing module within SplashCAD Desktop, glass processors can create and send a quotation to their customer instantly, all without leaving the system. Quotations are delivered via email and appear in the "My Quotes" section of their SplashCAD Online account.

Production Files.

When the job is ready for production, SplashCAD Desktop will generate all of the files required for the processing machinery. These include DXF and NC files (for example, waterjet/CNC Milling centres) and PDF drawings for job sheets. Support for Optima is also on its way. All these files are created from the original drawings entered by the customer so no data re-entry is required.

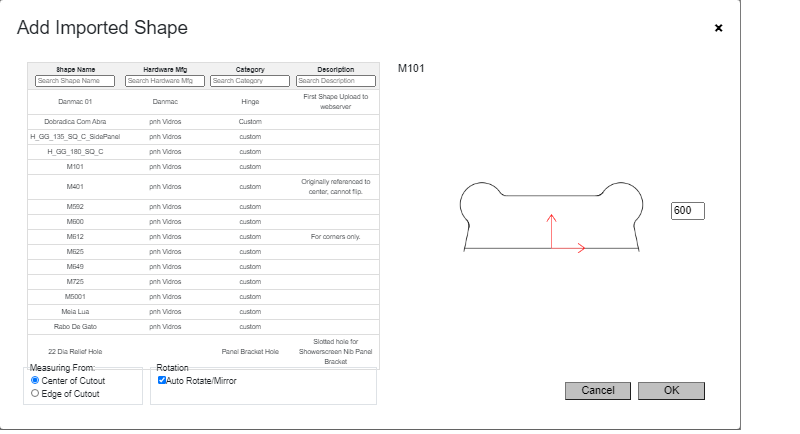

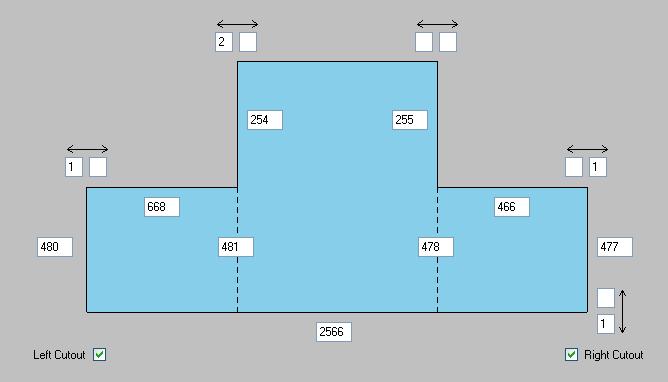

Cutout libraries.

Glass panels aren't just rectangular sheets of glass. They almost always contain cut-outs for different hardware, bevels and edges. These could be for hinges, wall brackets, door handles, wall sockets and much more. The geometry of these cut-outs varies greatly depending on the type of hardware and the supplier. SplashCAD has an integrated database of cut-outs that is always being added to. Users can create or import (from DXF) and upload custom hinges or submit them to SplashCAD for entry. SplashCAD aims to have the biggest online database of cut-outs for glass.

Once a cut-out is selected, simply drag and drop to process.

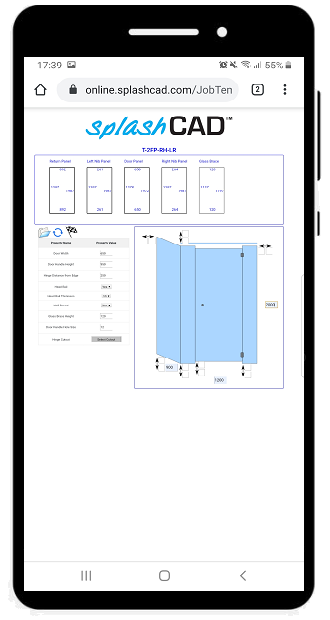

Job Templates.

Even though most glass panels are unique in size, jobs often have similar combinations of different types of panels. This is especially true with shower screens where the use of job templates is a game changer as they perform many complicated calculations automatically. For example, a frameless shower screen job made up of several panels has clearance gaps in between panels as well as walls and floor. To further complicate matters, these panels are often "out of square", so calculating each panel manually is not only difficult and time consuming, but very easy to make mistakes. Even with the use of spreadsheet calculators, data entry is still required by the glass processors for quoting and production. SplashCAD solves these problems with Job Templates.

Simply choose a template, enter the dimensions and the drawings are automatically created, with the ability to easily edit at any time.

New templates are relatively easy to create and add to the library, as they use the C# language in their scripting engine.

Alternatively the SplashCAD team can create Templates by submitting a request.

Of course, in addition to Job Templates, SplashCAD has many, easy to use Parametric Drawing Tools that make drawing glass panels easy.

Common shapes

are easily entered using the Outside Shape Wizard

Start using SplashCAD today!

Sign up for your free

SplashCAD Online

account now and be part of the future of the Glass Industry.

For Glass Processing companies that are interested in becoming registered supplier and receiving their orders via SplashCAD contact us.